General

Ultraviolet sterilizers are widely known for their ability to kill bacteria and viruses in water. They do this by passing UV energy through the water that disrupts the cells of the bacteria and effectively kills it. To do this the light energy must be strong enough to penetrate through the bacteria or virus and this of course requires a clear enough water supply to allow the light to penetrate.

Note: Having a water analysis done by qualified water treatment professional is essential to determine the levels of the following factors effecting the usage and ability of a UV system. They will properly size the system so it ensures a total elimination of pathogens in your water.

UltraViolet Transmittance

The water supply needs to be measured for its ability to allow UV energy to penetrate it. This is called ‘Transmittance’, and can be measured with a UVT meter. This reading is a must when assessing which type and size of ultraviolet system to install.

Water temperature

The colder the water temperature the less output the UV light system has. It is therefore a must to have a system with a quartz sleeve that the UV bulb sits in. This maintains an even temperature around the bulb and allows for constant output regardless of water temperature.

Particulate

All water has some colour or cloudiness although it can be hard to notice in a glass. Particulate in the water is relatively small. Particle sizes can be much smaller than the width of a human hair, or less than 20 microns. This means that they float in the water easily and must be filtered out before the UV light is applied. UV energy can only penetrate 10 microns into a solid substance. Therefore all particulate larger than this must be removed.

Turbidity

Generally when measuring turbidity a column of water is used against a scale, (on the bottom) and this gives you a reading of turbidity. Most UV systems are specified at a transmittance of greater than 95%. This would be the equivalent of very high quality water containing no sediment, iron, and very little dissolved hardness; much like reverse osmosis or distilled water. In normal circumstances ground water has a transmittance between 65 and 75% due to contaminants that are present. This means that the intensity of the UV system, (or output) must be increased or the contaminants must be removed.

Iron

A common contaminant in ground water iron in concentrations of as little as 0.2 mg/l can cause problems for a UV system. Iron tends to absorb the UV light and therefore it cannot penetrate to bacteria should the iron particles be large enough for the bacteria to ‘hide’ behind. High levels of iron can cause fouling of the quartz sleeve therefore not allowing the energy to pass through the water. Removal of iron can be accomplished by an iron filter or properly sized water softener.

Hardness

Levels of hardness in excess of 150 mg/l can be problematic for a UV system. The hardness deposits scale on the quartz sleeve because of the heat generated by the bulb. This then effectively keeps the energy from passing through the water and again not reaching the bacteria. High hardness in the water can result in frequent cleaning of the sleeve being required. It is best to remove hardness before hand with a good water softener.

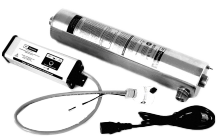

This UV system has higher output, (40mj/cm2) at flow rates of 32, 48, 60 litres/min. An integrated processor driven ballast controller gives the adaptability to adjust easily to any need.

Accessories include low voltage lock out solenoid and alarm, and special teflon encased UV sensor to inhibit fouling.