Ultraviolet light producing bulbs loose their ability to produce ultraviolet frequencies capable of killing bacteria progressively from the first moment they are plugged in and running. They loose approximately 1/2 their output over the period of 1 year. As almost all units are engineered on this basis, the effectiveness of the system dramatically reduces after the 1 year period.

There is also a protective coating put on the inside of the bulb that protects its and allows the output current from the ballast to remain constant. After approximately 1 year, the coating ‘burns’ off causing the ballast or power supply to drive harder and try to compensate for the lower output of the lamp. This stresses the ballast unit and therefore can cause damage to it, effectively burning it out.

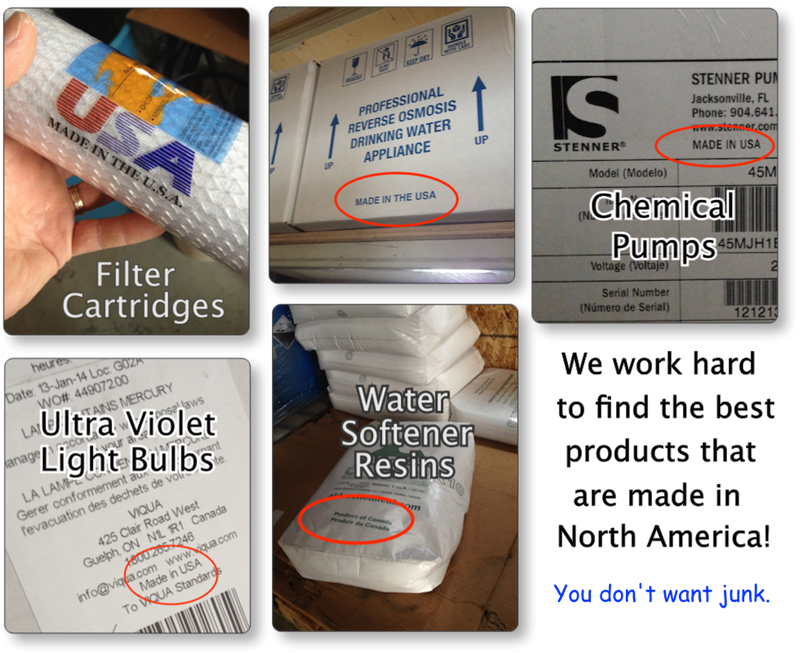

We assemble our own systems instead of buying them preassembled from the manufacturers. Why? So we can control the quality.

When orders are placed with our suppliers, we order different sizes of the mineral tanks, different grades of softening resin and quite a few different models of the control valves. After we come out to your home to test your water for hardness, iron, pH and TDS levels, we propose the best configuration to meet your needs.

Once you decide that you’d like to proceed, we custom assemble your system. Even though two water softeners or two iron filters physically look the same, there’s a good chance that they’re actually different. It isn’t logical to install a pre-made softener on Goderich lake water that’s chlorinated and then install the exact same system on non-chlorinated well water somewhere else in Huron County and then expect that they’ll both function the same.

When we assemble the systems ourselves, we know what media has been loaded into them. We know the exact capacity of each unit. We know exactly how each one has been configured. All information about each system is tracked in our records.

WHAT THIS MEANS FOR YOU – You know that you’ll have iron-free, completely soft water for years without maintenance issues because improperly sized or inappropriate equipment was installed in your home. Your water treatment equipment enhances your life by:

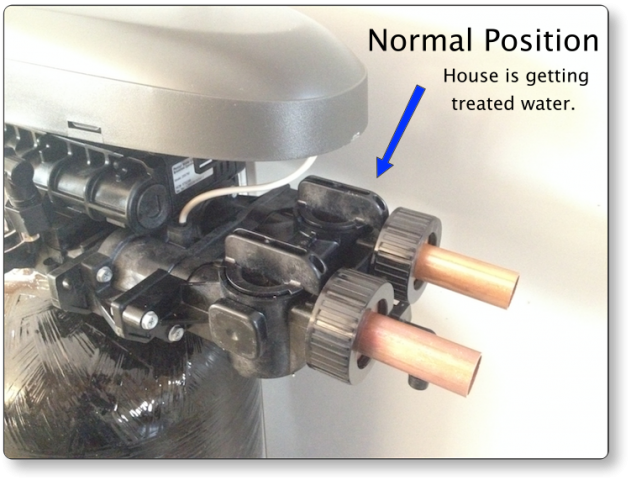

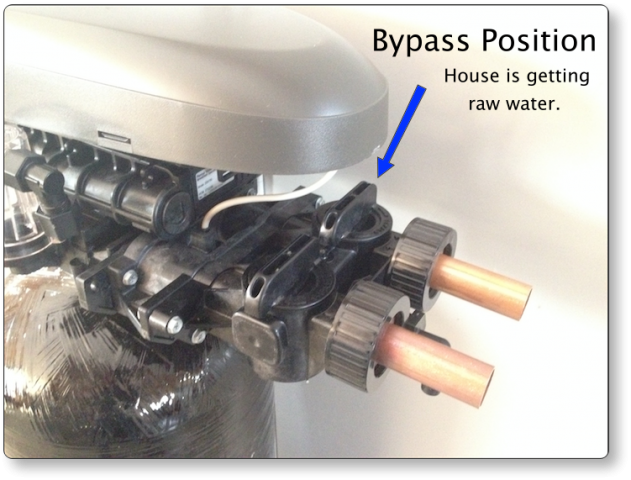

At the back of the control valve where the water lines are connected, most of our water softeners and backwashable filters have 2 ‘paddles’ that are sticking up. To place the system in bypass, use your hands and give both of them a 1/4 turn so they are lined up with one another. They will likely be very stiff and hard to turn so you might need to put some muscle into it. If you use a small pair of flat pliers, be careful you don’t damage the paddles or turn them further than a 1/4 turn.

Most likely the time on the clock is incorrect.

Most likely the time on the clock is incorrect.

Power outages from time to time will cause the clock to get out of whack. If the timer on your softener (or iron/sulphur filter) does not have battery backup, it will either loose its clock setting and flash constantly or it will come back on at the time it was when the power went out.

Reset the clock to the proper time and everything should be fine.

Most systems have been set to start regenerating at either 1am or 2am. This is because we want them to clean when no water is being used.

Add more salt when there is 6″ or less in the bottom of the brine tank.

A good habit to get into is to fill the brine tank to the very top, then let the salt level get down to near the very bottom before adding any more. By doing it this way, you’ll avoid maintenance issues that arise when the salt clumps together into a hard mass.

Over the years of servicing all the different makes and models of softeners, one of the most common problems we see is when a homeowner constantly adds salt to the tank to keep it full.

Although they had good intentions – “I didn’t want it to ever run out” – this habit can actually lead to problems.

When salt is constantly added and the tank never gets a chance to run low, what can happen is:

– the salt in the middle gets hard

– the water flows around this hard salt & dissolves the loose salt on top

– the water level in the tank eventually gets higher and higher until…

– you have a flood of salty water as it flows over the top.

Inside most of the brine tanks there is a plastic tube that protects the brine wand. This tube, which is often referred to as the brine well, either has holes drilled in it near the bottom or a series of slits that have been cut. These openings allow the water from the brine wand to move in and out of the area with the salt.

If the salt gets hard, it can block these openings off. If that happens, the water softener will not get enough of a brine solution to clean properly and you’ll quickly have hard water again. If your installation did not include a safety float in the brine well – you could have a small flood.

One question that we’re always asked is “how often should the drinking filters be changed?”

If we’re talking about a reverse osmosis system, the general rule-of-thumb is annually. This would be based on a family of anywhere from 2 to 6 people and assuming that the water entering the filters is free of hardness and iron.

If there’s only 1 person using the water, the filters don’t have to work as hard. In this case, less frequent maintenance perhaps every 2 years (to test the water, change the filters and flush the system) is often OK.

With a large family, or in areas where the incoming water is a problem, maintenance may need to be every 6 months. Because so much water is going through the filters – if it’s left for any longer – the production slows down to almost nothing and they run out of purified water.

Each situation is slightly different and we can customize our service to fit each individual need.

Unless you have a single carbon filter cartridge on the kitchen cold line (in which case you want it to be hard water), the reverse osmosis drinking systems should have softened water feeding into them.

Regardless of whether hard or soft water is fed into them, the water that comes out the faucet is completely free of any dissolved solids. No calcium. No sodium. It’s not hard or soft – It’s simply purified water.

But it’s easier for the system to remove the sodium from the softened water than to have to deal with the calcium that’s in hard water. If you examine your kettle, you see the buildup of hardness on it, then you understand how the RO membrane will look after time on hard water. The softened water doesn’t stick as bad so the system doesn’t get as scaled up.

The part of the system that the prefilters is protecting is called the membrane. There are many different membranes available on the market today. The membrane must be matched to the water and the system to work properly and effectively. This is where we come in matching the system to specific need and water supplies.

For most homeowners, if they have sent a water sample in to the Health Unit and received notice back that there are trace amounts of either e-coli or coliform, an ultra violet light disinfection system is the answer. Instead of shocking the well once with chlorine and hoping that the problem does’t come back, having a UV system in place ensures continual protection – 7/24.

Any living organism that passes in front of the light is exposed to a wavelength of 254 nanometers for a few seconds. In very simple terms, this is the perfect frequency to alter the DNA of the organism so that it mutates, can’t reproduce, and dies. This process renders the bacteria or virus completely harmless.

Unlike chlorine, the UV system doesn’t add any chemicals to the water that alter the taste, gives off a smell or have negative health effects.

In addition to bacteria and viruses, ultra violet light disinfection is very effective for dealing with cryptosporidium and giardia. These two pathogens are extremely resistant to chlorine.

Before installing a UV system, the incoming water should be free of iron and have very little or no hardness. Both these factors affect the transmittance level of the water (the ability of the light wave to travel through the water). Cloudy or murky water will dramatically decrease the lights ability to ‘kill’.

3 bags a month?

Half a bag per week?

12 bags per year?

The answer depends on a number of factors;

Hardness – The higher the level of calcium in your water (hardness), the more salt it will take during the cleaning cycle to regenerate the water softener. This is due to the size of the unit…

Size – Some softeners have a mineral tank that is 8″ in diameter. Others are 9″, 10″ or even 12″. Then, there are different heights of tanks. The average water softener ranges from 35″ tall to 54″ tall. The larger the mineral tank, the more resin beads it will hold…

Resin Beads – There are different grades of resin that go into the mineral tanks. Some are designed for pre-treated municipal water supplies that have a moderate level of hardness and no iron. Other resins are better suited for well water with both hardness and iron.

Control Valve & Timer – As with anything, you can buy low quality (often the cheapest), mid quality or high quality. Same goes in the water treatment industry. Some of the manufacturers are producing ‘retail’ grade equipment that are inexpensive to purchase but are very inefficient and use a lot of salt. Other manufacturers have purposely taken the time and effort to engineer and produce valves & timers that are extremely reliable and very efficient for salt usage. You get what you pay for.

As you can see there are many factors that affect the amount of salt you should expect to use in a softener, but the average usage with a good unit today will be between 5 and 8 bags of salt per year.

If you’re wondering if your existing softener is working properly, the only way to know for sure is to have an in-home inspection done. By assessing the state of the current appliance, usage, and water chemistry we can estimate how efficient your system should be and make any adjustments or recommendations.

There are quite a few building projects going on right now in Huron County.

The tornado of 2011 hit Goderich (at the end of Highway 8 past Seaforth & Clinton) right at its heart and left a trail of destruction in its path. Some home owners were fortunate enough to receive insurance settlements quickly and started to rebuild just a few months later. For quite a few though, it’s taken a long time to settle everything and building projects are just getting started.

Down the road in Mitchell, another building boom is under way. An entire new subdivision is being built adjacent to the golf course in the northwest corner of town. Mitchell has long been known as a great place to live and is adding to their population each and every year.

1. Consider if you would like to have a drinking system installed. It’s nice to have the space under your kitchen sink available to store your cleaners, dishwasher detergent and maybe a bag of potatoes. If the basement of your home is going to be completely finished with a drywalled ceiling, the only option (if you decide after everything is done) is to have the reverse osmosis system installed in that space under the sink. If you’re planning on having a separate faucet with purified water, a great idea is to have the tubing run through the walls and down into a laundry room or utility area during construction. Then, once the walls are all finished, the drinking system can be installed downstairs and out of the way.

2. Think about chlorine removal for the entire house. A lot of people get dry skin from showering in chlorinated water. The chlorine has done its job killing any bacteria that might have been in the water supply, but now that it’s in your home – it’s time to get it out. A backwashable carbon filter is designed to filter all the water that enters your house and clean itself every few days. Once the chlorine residual is gone, so is its nasty odour and taste. In preparing for this system, consider having a floor drain installed in the utility room so there’s a place to drain the wastewater. Another option for chlorine removal is a special attachment that can go inside certain models of water softeners – which leads us into the third point.

3. A water softener removes hardness (which is calcium). It does this by passing the water through a resin bed and exchanging the calcium ion for a sodium ion. However, this process will not remove chlorine. There is an optional attachment that is available for some softener makes & models which can be installed inside the mineral tank underneath the control valve. With this setup, you get a triple benefit – perfectly soft water, no chlorine taste or smell, and a single system to treat all your ‘working’ water. As mentioned with the backwashable carbon filter, if you’re thinking about having a water softener installed, plan in advance and have an appropriate drain plumbed in.

There’s a lot to think about when the construction is going on – we know that. But taking a few minutes now to plan for your water treatment needs will make your decisions easier when the time comes.

On alot of the water softener service calls we go on, once we have tested the water and examined the unit, it’s often determined that the primary cause of the problems has to do with the salt.

The top left picture is a classic example of a salt bridge. The water softener has gone through numerous cleaning cycles and dissolved ALL the salt in the bottom half of the brine tank – leaving a ‘bridge’ of super hard salt above the water line. When the softener goes into the ‘brine draw’ part of the regeneration cycle, instead of sucking in a strong solution of sodium chloride, all it gets is straight water.

Using a large slotted screwdriver (and a fair amount of physical work), the bridge has to be broken apart until it collapses into the water below.

Another common problem is when the salt clumps together into a mushy, gooey mess. The middle picture above shows how some brands of evaporated salt can create big problems. When the clumping gets really bad, the water level in the brine tank will gradually rise and eventually overflow – either around the lid or out the ‘overflow port’ on the side. The salty water gets all over the floor and evaporates, leaving the salt behind. The salt that comes in the wavy chunks seems to have the most problems with clumping together.

Every 5 years, thoroughly clean out the brine tank. This can be a bit of a messy job so be sure to have lots of old towels (and maybe a mop) readily available. You’ll also need some buckets and something to scoop with.

Start by scooping out any water that is in the tank. Once you’re down to the salt, scoop out as much of it as you can as well.Your goal is to make the brine tank as light as possible because the next step is to disconnect it from the softener control valve and carry it outside. Once you’ve located a place where you don’t mind washing away the remaining salt, use the garden hose to completely wash out the inside of the tank.

Be sure to blast some water down the brine well where the brine wand is located. The one area you need to ensure is completely free of any residual salt is at the bottom of the brine well. Depending on your model, there will either be a series of slits cut into the plastic tube or there will be a platform with a series of small holes in it. Either way, be sure to wash away all the remaining salt.

Take the brine tank back indoors and reattach to the control valve. Dump in a few bags of clean, new salt and then pour in enough clean, fresh water to fill the tank up to about 1/4 – 1/3 full. Manually start the water softener into a regeneration cycle. When the cleaning cycle is done, the cold water will be conditioned again and completely soft. Depending on the size of your hot water tank and the size of your family, the hot water will be completely soft again in a few days.

If problems still exist after you’ve cleaned out the brine tank, the water softener might need some additional service.

To avoid having problems again in the future, get in the habit of letting the salt run low in between fill ups. Instead of always keeping the salt tank more than 1/2 full, let it run down until there is only 6″ of salt left in the bottom. At that point, add enough bags of salt to bring it back up near the top. By doing this, we’ve found that our customers have a lot less problems with bridging and clumping.